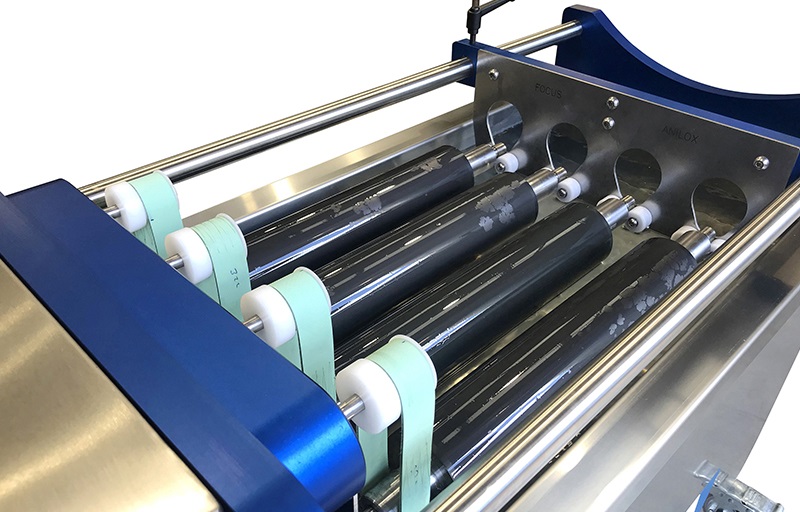

In printing, primarily in flexographic and offset printing, anilox is a procedure that plays a major role in providing the required amount of ink to a flexo printing plate.

Anilox roller is basically a ceramic roller or an engraved metal roller brought into the printing press to transfer the ink from the roller to the printing plate. Its main purpose is to pick the ink from the roller or from any of the configurations and deliver a uniform amount of it to the rubber plate for the printing process.

Due to the regular use of anilox rollers for printing work, chances become high that these start delivering low-quality prints. Proper maintenance and cleaning are thus essential to get the ideal printing results along with durability and longevity for the rollers.

How to Clean Anilox Rollers?

Cleaning the anilox rolls starts with a few essential guidelines not following which may lead to rolls becoming even dirtier, which can be time-consuming and difficult to clean.

- Do not remove the rollers if there is ink remaining in the system.

- As soon as the rolls are taken out, ensure that you wipe them out and clean them with a high-quality cleaner solution.

- If the ink is allowed to dry and deposit on the cells, it becomes too hard to remove.

- In addition to performing daily cleaning of the rolls (after each new set-up) you may need to deep clean them (usually every 2-3 months) to achieve the best performance and durability.

A few basic methods for cleaning your anilox rolls and getting enhanced printing results are as follows:

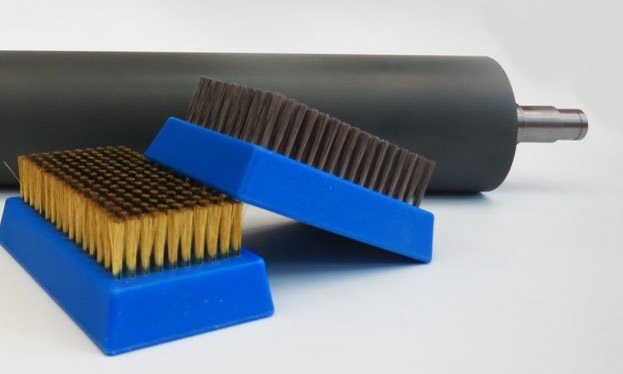

1- Brushes

If you love DIY tasks and want to handle anilox roll cleaning manually, you can use anilox roller cleaning brushes that can help clear the minute cells in the roller in a safe manner.

High-quality brushes made of brass, stainless steel, and horsehair (or nylon) are recommended for cleaning the anilox rolls and can be purchased online at a low cost. These do not damage the sensitive parts that perform the printing work on the plate.

If you are not pretty sure about the brush type or quality, you may get in contact with your anilox roll manufacturer to get an idea about the best type of brushes and tools that can be used for your specific roller type.

2- Blasting Method

Cleaning anilox rolls can also be done using a technique that involves blasting the anilox surface with baking soda or sodium bicarbonate (NaHCO3).

The fine particles of baking soda, which are smaller than the cell openings, are air-blasted on the rotating roller surface. These reach deep into the surface and fight the unwanted deposit materials. A vacuum is then used to clean the surface from baking soda and remove material.

The technique mentioned above works great for rollers that employ the usage of water-based ink. You may, therefore, need to check your roll type before you use this technique.

3- Aggressive Chemicals

Deep cleaning of the anilox rolls using aggressive chemicals, solutions, and ink-specific solvents is advised every 2-3 months.

In this method, the roll is first treated with an ink-specific solvent to separate the bonding materials from the ink. They are then blasted with heated chemical agents or an alkaline wash.

Chemical anilox cleaning in a machine can prove to be much more effective, especially when you choose good ink-specific solutions that are user and environmentally friendly. However, be aware that upon choosing the wrong chemicals/solvents, the rollers can get corroded or completely damaged, which is hard to recover.

4- Laser Cleaning Method

To avoid the inconvenience and nuisance that can be caused by chemicals, anilox laser cleaning is also many times recommended. The laser beam here can leave a high impact on the ceramic surface of the rollers which leads to contamination getting free from the dirty surface.

The so-called method of cold evaporation (which is dry and gentle) proves to be effective and can take from 40-45 minutes to complete. However, care has to be taken that it requires proper knowledge and experience to achieve the right settings of anilox rotational speed, laser beam scan width, etc.

5- Ultrasonic Cleaning System

The ultrasonic cleaning technique is the fastest method that can clean up to 90% of the contaminants in a much faster and convenient way.

The ultrasonic anilox cleaning device employed for the task handles the cleaning process on its own; for this reason, there is no need to let an additional person watch the cleaning process.

An automatic ultrasonic anilox cleaning machine, through the sound waves and cavitation process, reaches the depth of the roller and clears any residues of the ink or liquid from the holes, crevices, and internal chambers.

These cleaners provide a pre-determined frequency operated independently with a low-voltage supply. To get the best cleaning results, it is recommended to make use of a heated cleaning solution in an ultrasonic anilox cleaner which is specifically formulated for the cleaning task at a specific temperature, as recommended by the industry experts.

Signs That an Anilox Roller Requires Cleaning

Your Anilox roller might be screaming for attention if you see some of these common signs:

- Doctor Blades Are Having a Hard Time: Excessive wear on these little warriors might mean hardened gunk is hitching a ride on your roller’s surface. If you’re cranking up the pressure to transfer ink, clogged cells could be the culprit.

- Ink’s Playing Hard to Get: Is the roller under-delivering ink? Residual buildup in the cells might be playing spoilsport.

- Streaky Prints Are the New Norm: Visible streaks, light ink coverage, or faint lines in your prints are waving red flags—clogged or damaged cells aren’t pulling their weight.

Keep in mind that when it comes to anilox rollers, Mother Nature can be a real troublemaker as temperature and humidity can impact their performance drastically.

High temperatures? They’ll make the roller swell up like it just ate a giant burrito, risking misalignment or warping. And if you’re dunking the roller in a hot chemical bath for cleaning, don’t be surprised if the ceramic or chrome coating decides to take a vacation early.

As for humidity, it’s not just about sweaty palms; it can rust up the metal parts of the roller and mess with drying times. If the roller isn’t properly dried, you might end up with some sticky residue that’s harder to get rid of than an uninvited guest.

Want to keep your rollers in top shape? Invest in training programs to turn operators into anilox whisperers, armed with the skills and know-how to handle them with care.

And here’s the tech twist: IoT + AI = Roller Supervision 2.0. With real-time data collection, predictive maintenance, and intelligent decision-making, these tech buddies can transform cleaning schedules, boost efficiency, and make your operation as smooth as fresh ink on a pristine print.

The Conclusion

Selecting the right anilox roll cleaning system is crucial for maintaining optimal performance and print quality.

Whether you’re opting for advanced ultrasonic cleaners, automated systems, or eco-friendly options, the key is to choose a solution that fits your specific needs while minimizing potential damage to the delicate cells of the roller, ensuring longevity and precision.